Products

The time-saving joining system with positive-locking anchorage

The original for efficient, intuitive and precise joints

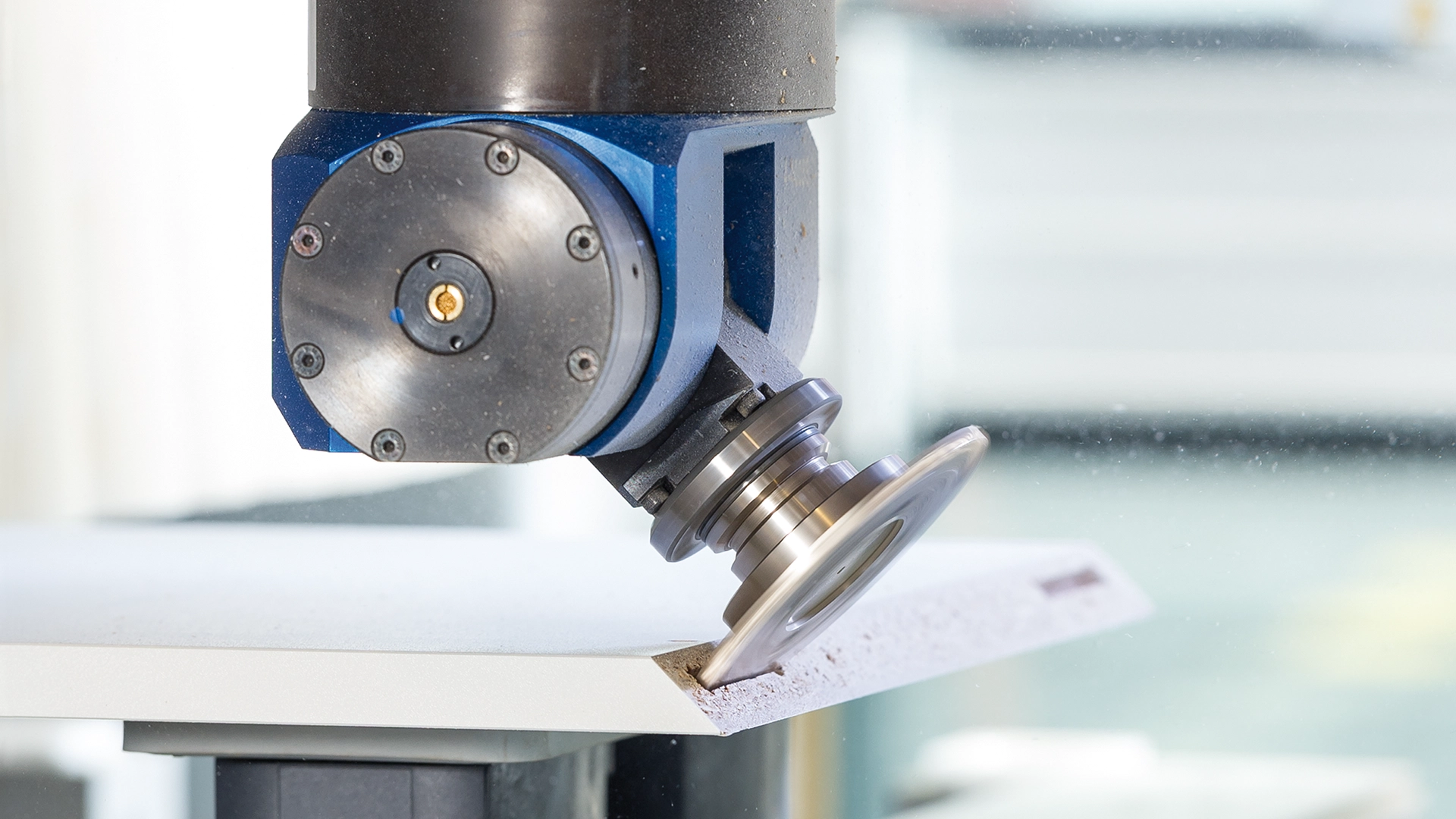

Unique drilling systems for high productive and aesthetic demands

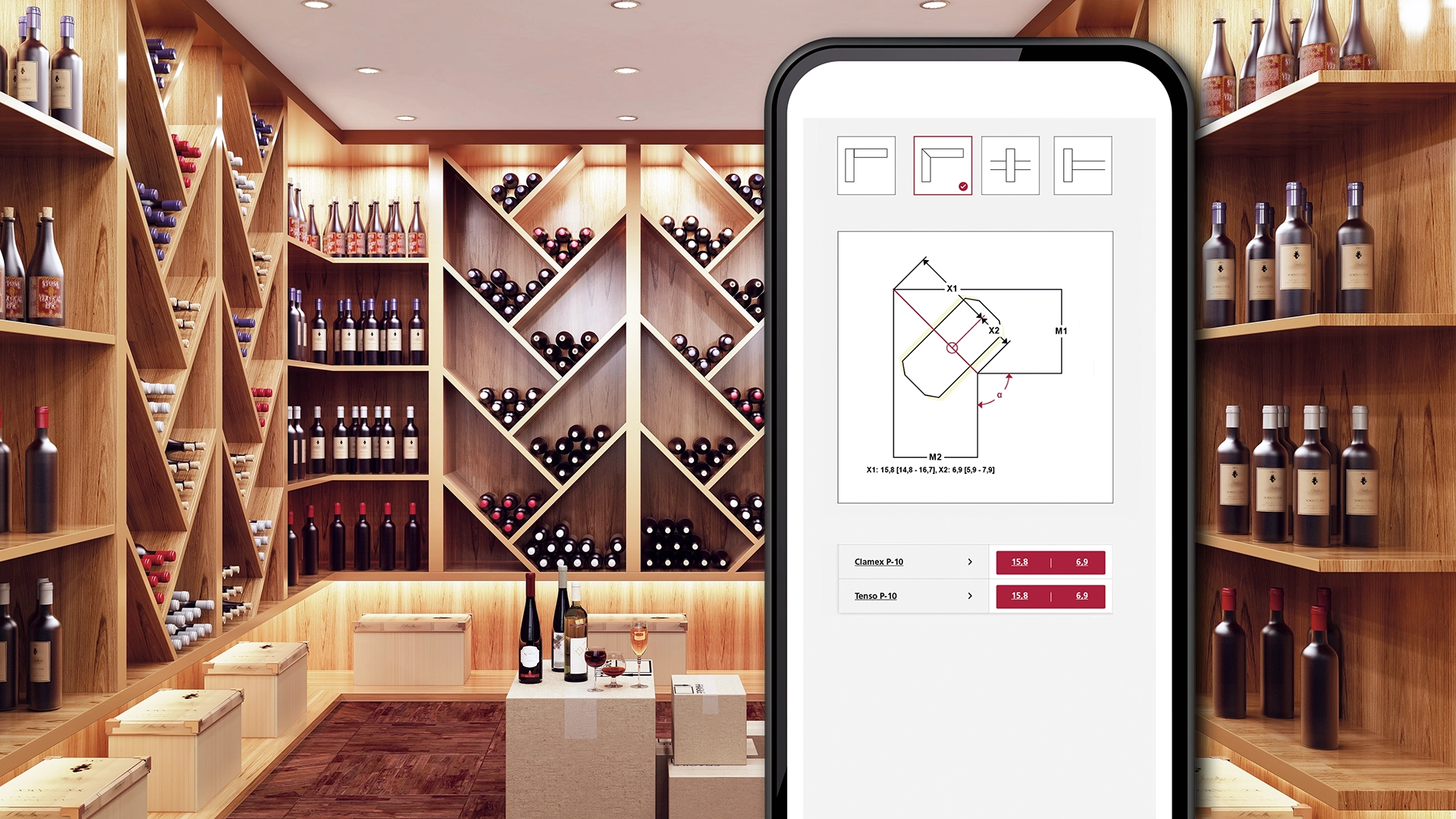

Software components for the efficient use of Lamello products

Application inspiration

Solutions

Inspiration

![[Translate to UK:] [Translate to UK:]](/fileadmin/user_upload/Navigation/Loesungen/Kundenreportagen.webp)

Fresh from the press: Lamello customers reveal why they choose Lamello connectors

Fresh from the press: Lamello customers reveal why they choose Lamello connectors

Discover a wide range of application inspirations joined using Lamello products

![[Translate to UK:] [Translate to UK:]](/fileadmin/user_upload/Navigation/Loesungen/Planungs-_und_Bearbeitungspartner.webp)

Reasons and principles for integrating Lamello connectors into your production

Reasons and principles for integrating Lamello connectors into your production

Has your production software integrated the Lamello connectors? Read more about it here

Discover the advantages of Lamello biscuit joiners and their efficiency

Find the right connector and the correct installation position in next to no time

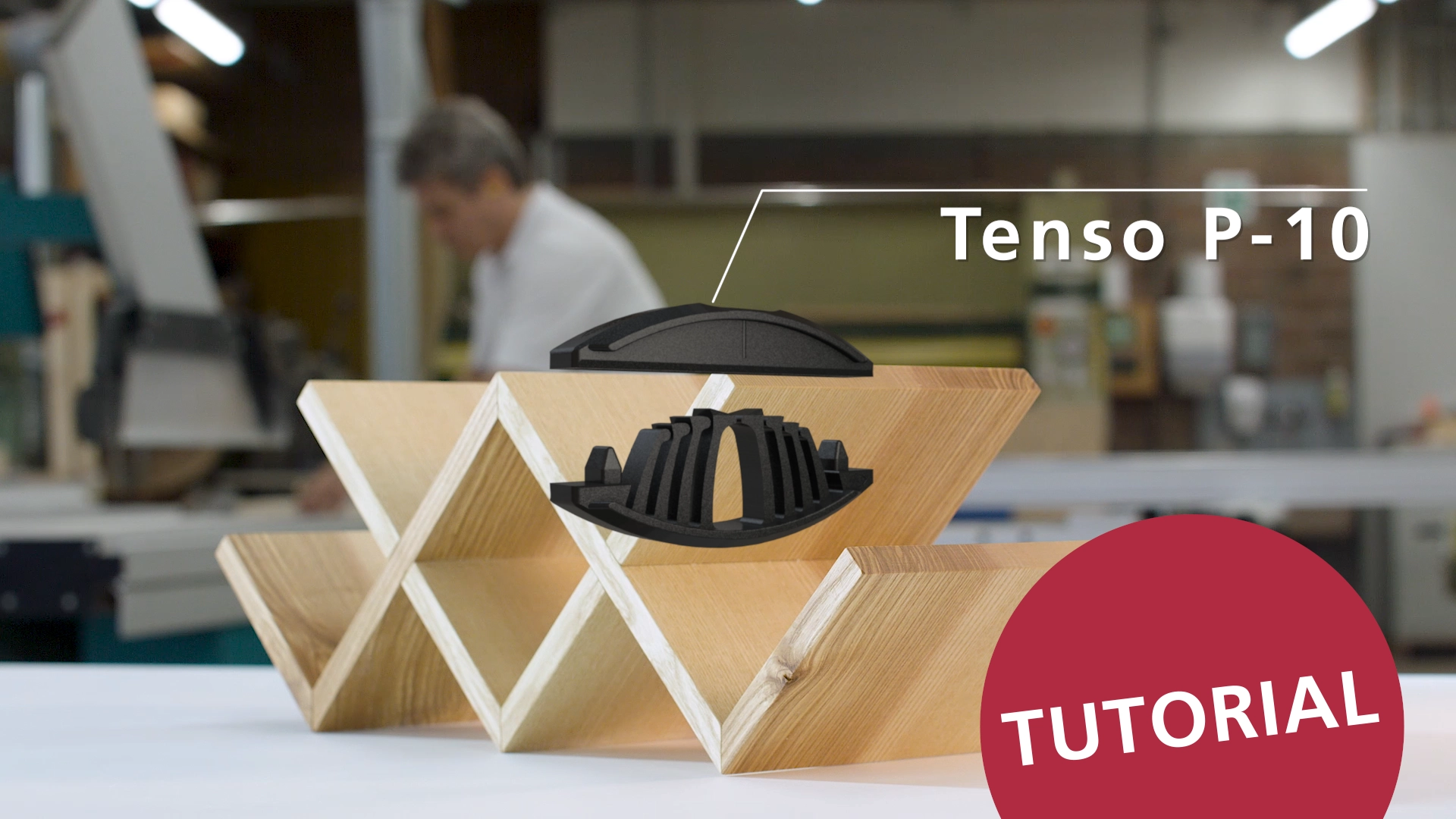

The use of Lamello products in different applications explained step by step

Service

Find out more about the servicing, maintenance and repair of Lamello machines

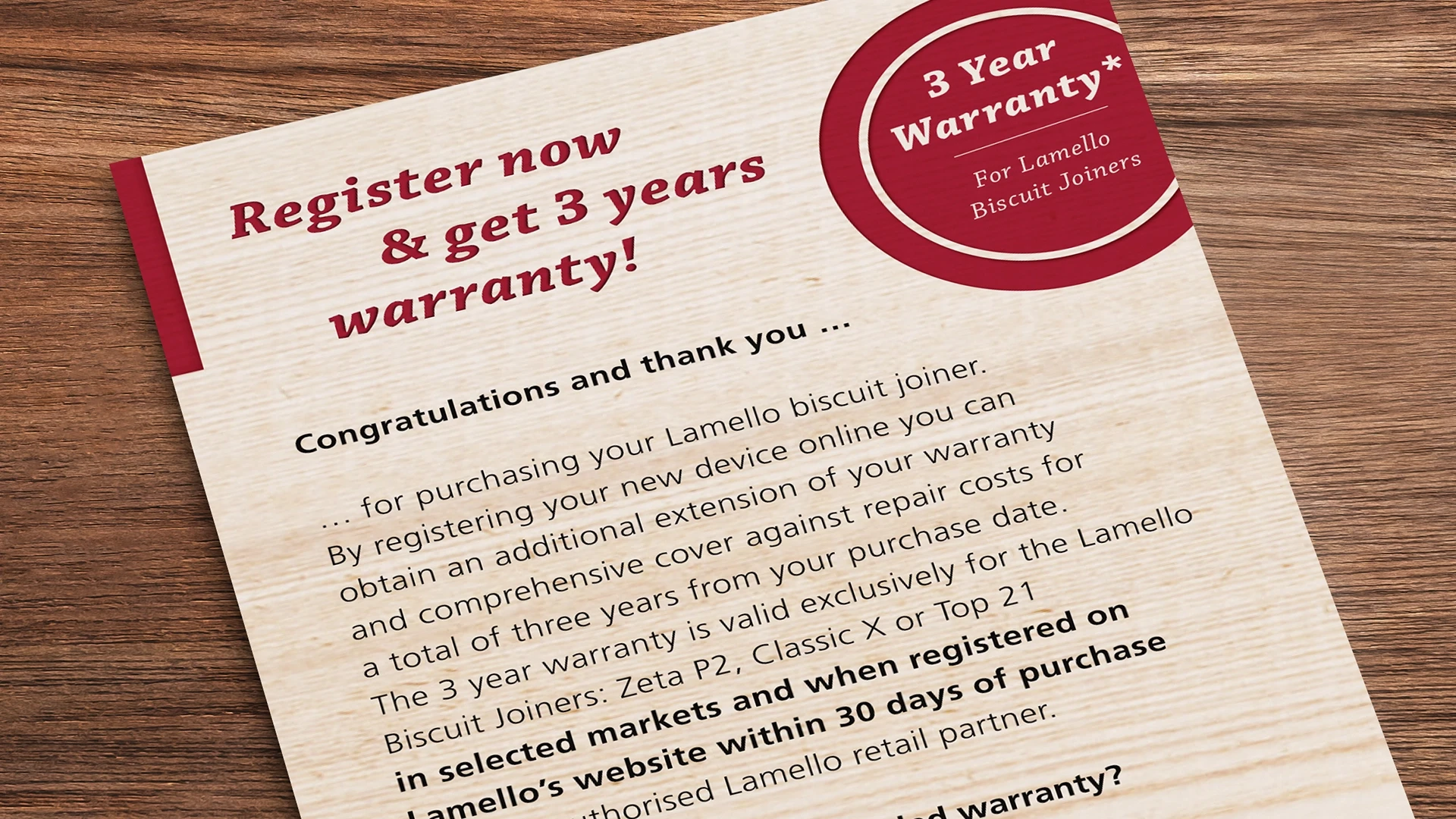

Register your Lamello machine now and get a three-year warranty

Find the correct spare part or accessory for your Lamello machine here

Contact

Find your nearest Lamello specialist

Do you have any questions about our products and services? We will be happy to help you.

Experience Lamello live – we look forward to your visit

Subscribe to get the latest product news and all sorts of inspiration

Company

Lamello keeps its promises

Flexibility, productivity, creativity – our innovations meet your needs

Far-reaching. Close to home. We are there for you worldwide

Beech wood from sustainable, locally managed forests is just the beginning

People at the heart of the Lamello organisation

Solutions

Contact

Application inspiration